Ape Automazioni s.r.l. - Rezzato (Brescia)

Overhaul of electric boards for injection presses and other industrial machines

Via Naviglio, 25 - 25086 Rezzato (Brescia) | Tel. +39 030 2791889

Email: [email protected]

Our long experience and the deep knowledge of plastic injection presses field, allow also to operate also on obsolete machines and bring them to a new life.

Overhaul of electric boards for injection presses and other machines

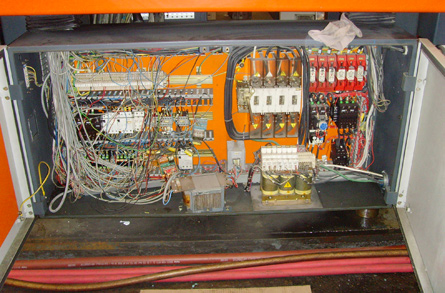

Electric board o fan injection press before our intervention

|

|

|

Overhaul electric boards: |

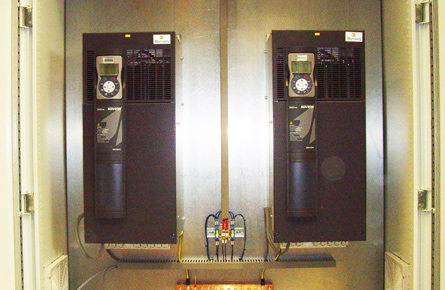

Overhauled electric board |

How we make overhauls

The synergies we have been creating for many years with our partners, make our Company versatile in any technical field, from hydraulic systems to programming s.w. and, thanks to our production flexibility, we are in a position to make any injection press perfectly matching with Customers’ needs.

We mainly operate on high tonnage presses; therefore, our strength point is our capability to carry out a complete overhauling without moving the machine, with a consequent huge advantage in terms of costs and immediate net saving of logistic expenses.

Working at Customers’ places, we can carry out efficient interventions all over the World. Before starting the revamping operations of the press, we carefully check the machine in order to evaluate the actual wear conditions, and decide how to proceed.

During this phase, we also analyze the power consumption of the press, in order to check its efficiency, and to supply suitable solutions which will optimize the performances of the machine also in terms of energy saving.

At our plant, we prepare all parts subject to intervention such us:

- Brand new electric board (if possible, the old one will be retreated)

- All necessary parts for any on board intervention

- Highly performing and user's friendly latest generation PLC, with touch panel

- Possible new equipment, complete with inverter for a remarkable energy saving.

As soon as the necessary material will be received by the Customer, our technicians will carry out the necessary jobs. Depending on the machine sizes and intervention difficulty, in some 6 to 10 days, the revamped press will be able to guarantee the same performances as a brand new one.

Touch panel, new operating system, overhauled injection press

Inverter board for injection presses